| iX Interio is the ecosystem for furniture manufacturers and interior designers that enables new digital cooperation models: Suppliers, manufacturers and end customers are connected with each other - even beyond company boundaries. |

- Discussing 32mm and face frame cabinet construction including fabrication, casegoods design, and installation. CAD Forum Shedding light on the all-too-often shadowy world of CAD. CNC Forum Discussing CNC (computer numerically controlled) woodworking equipment, software, and automated product manufacturing.

- Imos accompanies the manufacturers of furniture and interior furnishings from sales through planning, presentation and design to production. The industry-specific 3D design tools are linked with modern machines and new communication platforms. In this way, individual pieces of furniture or complex interior design concepts can be realized.

- IX Interio is the ecosystem for furniture manufacturers and interior designers that enables new digital cooperation models: Suppliers, manufacturers and end customers are connected with each other - even beyond company boundaries. From networked applications to the ecosystem iX Interio is the.

From networked applications to the ecosystem

iX Interio is the result of developing autonomous software applications to integrated solutions that fulfill the requirements of digitalization and overcome both technological barriers and company boundaries.

iX Interio is based on a series of applications and databases. The key component is the central product database, which dissolves the interfaces in the process and provides reliable information at all times. The integration of adjacent systems such as ERP or MES is largely standardized via the Integration Server. Depending on application and user group, both desktop and cloud-based applications are used.

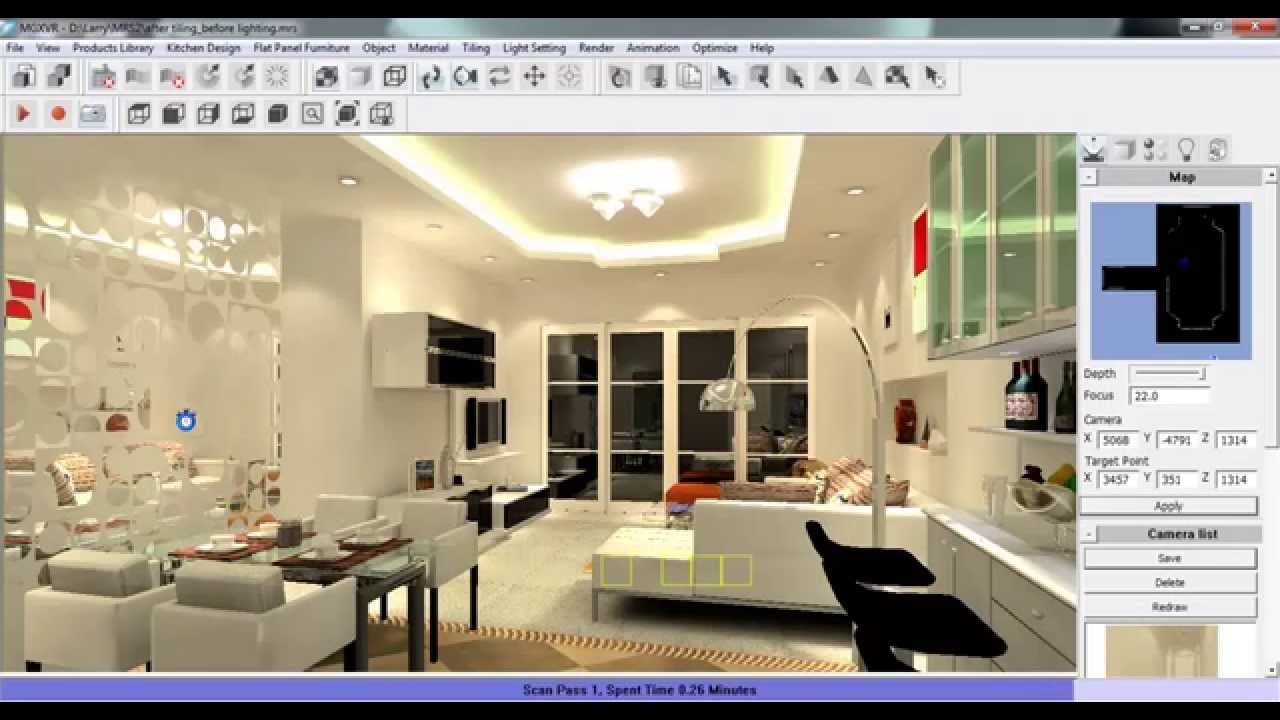

Creating a custom kitchen cabinet from scratch in imos CAD/CAM software in just 2 minutes. Complete with all connectors, blum tandem drawers, blum aventos d.

Benefits of iX Interio

- Integrated – No interfaces

- Consistent – Continuous flow of master and transaction data between user groups

- Secure – Integrated database

- User-friendly – Scalable customized applications

- Standardized – High maintainability of the system

Integrated & smart

We develop specialist software solutions for the furniture and interiors industry. Supplying companies worldwide with CAD|CAM software to aid their design, manufacturing and distribution processes. From individual retailers to industrial mass producers, our software platform combines multiple processes including online E-commerce, design and analysis, automation of production facilities, and the integration of existing IT solutions.

Our users include small and medium-sized companies that manufacture highly bespoke items as well as leading mass producers in the industry. We also supply web-based solutions and services to the component and hardware sector in order to provide their digital product data quickly and easily to the furniture development process.

SMART CHECK

IMOS READY?

We offer a complete software solution from sales to manufacture. Start the ‘Smart Check’ and find out, if imos is the right software for you!

Your Solution

Congratulations! We have exactly the right software solution for you. Please feel free to contact your imos AG representative directly at:

As it stands, our standard solution does not seem to fit your needs. We will gladly work out an individual approach with you. Please contact your direct contact at imos AG and get advice:

Anything in here will be replaced on browsers that support the canvas element

our strengths

Integrated Software

From sales through planning, presentation and design to production - all with one solution.

Mobile Sales

Cloud-based presentation and ordering systems for furniture and room planning in 3D. Support the sales process and include the customer in the design process.

International

34 sales partners take care of the needs of more than 4,000 customers in more than 80 countries - including individual support and advice. The imos software is also available in 27 languages.

Supply Data 24/7

The extensive catalogue for supplier data supports the selection and use of materials, profiles and fittings - always up-to-date and available online.

Construct easily in 3D

3D software tools for parametric and free form designs, fulfil all requirements that users need for variable designs.

Directly to the Machine

Planning and construction data is converted directly into machine-readable formats, for all common machines.

Smart Fittings - Offline & Online

Fitting conditions in the construction is analysed, suitable hardware fittings are selected and are positioned according to parametric rules.

Solutions from the Technology Leader

When designing furniture, all construction methods are possible, changes are allowed at every phase, and production standards are maintained in-house.

software worldwide

We offer software for more than 4,000 companies in 83 countries around the world, including leading international kitchen and furniture manufacturers and design-oriented interior specialists.

Muylle Family, Owner

Dovy keukens, Belgium

We started with imos in 2010 as one of the first companies in Belgium.We have chosen imos because the software offered us the possibility to integrate our own ERP-system in their program.The integration took a lot of work and efforts but the result is a program that gives us the possibility to control all the processes in our production.As we are a kitchen firm that manufactures custom made kitchens, we really needed a flexible program.

Hans De Keyzer, Management

dekeyzer, Belgium

The company decided to invest in a CAD/CAM system in order to optimise the information flow between the interior architect and the production.imos is easy to use for the interior architect and in the same time it has the capability to define complex articles that can be produced in our production facility.

Mikko Harmanen, CEO

VISU Kaluste, Finland

“Last years we have invested a lot in new production machines and we want to use them in the best possible way. With imos we connect sales, product/project design, manufacturing design and machine woodworking data to one comprehensive solution. This modern way of doing things makes everything so much easier, flexible and error resistant.”

Leo Kingston, Operations Director

Spacestor Ltd., United Kingdom

“With imos, we now have a CAD/CAM software that not only lets our project managers and production designers create presentation drawings and visuals, but also the required paperwork and reports that our estimators and project co-ordinators need in order to track a job though.”

Chris Revelman, Owner

Coors Interieurbouw, Netherlands

“Product security is very important to us; there must be a flawless transmission of information between preparation and production. With imos you are certain of this: if the preparation is good, then you know that the sequel is in accordance with it.”

Glen Lincoln, Owner

Hawk Furniture, United Kingdom

“imos has also allowed the company to grow without the need for additional staff. It provides more professional and more detailed drawings which isessential in reducing problems with the customer understanding exactly how their product will be made.“

Rene Blom, Owner

Sebo BV Interior & Equipage, Netherlands

“The use of imos makes it easy for SeBo Interior & Equipage to make adjustments according to the customers’ specific wishes and visualize them again for the client.”

Werner Thelen, CEO

Anton Thelen GmbH, Germany

'We have been working successfully with imos for years, because the software supports us in all of the individual room plans perfectly and directly enables production in our modern machine park.'

Philipp Heiss, Authorized signatory + Division Manager Interior Manufacture

Baierl & Demmelhuber Innenausbau GmbH, Germany

'An innovative and modern production with latest production machines requires up-to-date software for controlling and programming the systems.baierl + demmelhuber opted for imos and dealt intensively with the matter from the beginning. So now we can fully exploit the potential of the software and significantly increase our effectiveness long term.'

Ambadas Kamurthi, Owner

Ambadas Kitchens, India

'imos increases the reliability as a software and increases productivity.'

Udo Van Bekkum, Owner

Van Assem Interieurbouw, Netherlands

“Recently we took the next step in the automation, looking for a 3D drawing package that offers the complete solution for the production of furniture.We see imos iX as the new standard for the market and it also met all our specific requirements. imos iX was therefore a good choice for us to take the next step towards industry 4.0. “

Alexander Ehm, CEO

Ehm & Eitel GmbH, Germany

'We have been using imos since 2005. It has become a mainstay in our close-meshed work preparation and production, and our product is an indispensable part of maintaining our capabilities. We are pleased with the continuous development and always friendly service provided by the company imos.'

H. Krupka, Technical Director

Häcker Küchen GmbH & Co. KG, Germany

'With the help of imos, our variety of variants could be modeled and structured in a modular way and creates a significant increase in productivity in day-to-day business.'

Valluri Srinivas, Owner

Hi iN Concepts Private Limited, India

'After a careful study of roughly five solutions, I found, that imos is very intelligent in its core and is best for any kind of customized furniture design & production, imos solution has great capability to scale up furniture business operations.'

Thomas Pietsch, Authorized signatory and production manager

INUMA GmbH, Germany

'The introduction of imos has immensely optimized our workflows and process flows. Especially for fittings and various connection situations not only the error rate but above all the manual reprogramming could be reduced enormously.'

David Zisser, IT Project Manager

Neue Wiener Werkstätte - KAPO Möbelwerkstätten GmbH, Austria

'imos CAD / CAM has been a very important part of our work preparation since 2003 and supports us in the simple handling of the most individual orders. All required machine and partlist data is automatically generated from imos and reused directly on the machines.'

Tomasz Bardzik, COO & CTO

Nowy Styl, Poland

'Implementation of the imos solution has allowed us to significantly automate the process of generating data for production systems. imos has supported us not only with software, but also with knowledge in the field of automating data generation processes.'

Peter Hay, Owner

Imos Interior Design Software Price

Peter Hay Kitchens, New Zealand

“In our 43 years of business we have used or seen several software systems. For Peter Hay Kitchens, moving to imos has seen huge gains in the transfer of data to our automated manufacturing process. This combined with our front end imos drawing program, has also seen greater control in costs.”

Matthias Thannbichler, Operations Manager

Schuster Hoteleinrichtungen GmbH, Germany

Imos Ag Interior Design Software

'We have developed from a furniture producer to a complete outfitter for hotels - always accompanied by imos. The key to this is the modular structure of the software, integrated functional improvements and a qualified service. From our point of view, this is the guarantor for a successful improvement of the operational processes and ultimately an important component of the company development. '

Imos Interior Design software, free download

Gholamreza Eftekhari, Owner

Faza Gooya, bpert.com, Iran

Imos Interior Design Software Reviews

imos is for us the major tool in business. We started in 2016 with imos CAD to design our furniture in a parametric way. 2018 we launched www.bpert.com based on imos technology. Our goal is to develop the market, educate our clients to order online and directly import the orders to our production system, based on imos technology. Many thanks to imos!